-

High Power DC Electronic Load Model 63200A series

- Đăng ngày 27-03-2019 09:18:59 AM - 2408 Lượt xem

- Mã sản phẩm: S000127

-

The 63200A series high power DC electronic loads are designed for testing a wide range of power conversion products including AC/DC and server power supplies, DC/DC converters, EV batteries, automotive charging stations, and other power electronics components. These units can be synchronously paralleled up to 240kW and dynamically synchronized for generating complex multi-channel transient profiles. The 300% peak overpower capability provides extra headroom for fault condition simulations in automotive batteries, fuel cells, and more.

Key Features:

- Rated power: 2kW, 3kW, 4kW, 5kW, 6kW, 12kW, 18kW, 24kW, Max. 240kW (Parallel)

- Voltage range: 0-150V, 0-600V, 0-1200V

- Current range: 2,000A max. per unit

- CC, CR, CV & CP operation modes

- CR+CC, CR+CV, CC+CV complex modes

- Up to 10 units master/slave parallel control

- Dynamic synchronous control in static and dynamic loads

- User defined waveform (UDW)

- CZ mode for turn on capacitive load simulation

- External loading current simulation

- Auto frequency sweep up to 50kHz

- Real time power supply load transient response simulation & Vpk+/- measurement

- User programmable 255 sequential front panel input status

- Ultra high precision voltage & current measurement

- Precision high speed digitizing measurement/data capture

- Voltage, current & Pmax measurement for OCP/OLP tesing

- Timing & discharging measurement for batteries

- Instant overpower loading

- Short circuit simulation

- Smart fan control

- Full protection: OC (adjustable), OT,OP (adjustable) protection & OV warning

- Standard USB, optional Ethernet and GPIB interfaces

The 63200A series high power DC electronic loads are designed for testing a wide range of power conversion products including AC/DC and server power supplies, DC/DC converters, EV batteries, automotive charging stations, and other power electronics components. These units can be synchronously paralleled up to 240kW and dynamically synchronized for generating complex multi-channel transient profiles. The 300% peak overpower capability provides extra headroom for fault condition simulations in automotive batteries, fuel cells, and more.

The 63200A series have three operating voltage choices, 150V, 600V & 1,200V, with models covering power levels from 4kW to 24kW and up to 2,000A in a single unit.

The DC loads have unique user defined waveform (UDW) capability and external analog modulating input for s imul a t ing re a l-wor ld, cus tom waveforms. Another distinct feature is the dynamic auto-frequency sweep function, which enables detecting a UUTs worst case output deviation across a wide range of current frequencies. In addition, a 255-set of data storage function has been built in for recall of the stored settings at any time. For automated testing, the save and recall functions can save a great deal of time.

As each model of the 63200A series has 3 power ranges, they can precisely measure the voltage and current in real time. Since short circuit testing is one of the essential power testing items, the 63200A series provides short circuit simulation to effectively solve the application demands for power and automated testing.

With the vacuum florescent display (VFD) and rotary knob, the 63200A series loads offer versatile front panel operation. Users are able to control the 63200A family remotely via standard USB or optional Ethernet and GPID interfaces.

The embedded PWM fan speed control reduces noise caused by fans. The 63200A series also have overcurrent, overpower, and over temperature protections as well as over voltage and polarity reverse alarms to enhance product reliability. These DC loads are rel iable produc t s for engineering testing and automated test system's integration.

APPLICATIONS

ULTRA HIGH POWER DENSITY & USER-DEFINED HOT KEY DESIGN

Chroma's 63200A series high power electronic loads with digital signal microprocessor (200MHz) built in have the optimal speed and control performance. The ultra high density power (6kW@4U) not only saves room, its super high voltage (0.015%+0.015%F.S.) and current (0.04%+0.04%F.S.) measurement accuracy ensures the fidelity of results. In addition, the entire series can either be operated by hand or controlled remotely. For higher power demands, master/slave control can be used to parallel multiple units for operation. These electronic loads also have synchronous loading capabilities to simulate the actual loading status.

The world leading ultra high power density design overturns the concept of oversize and difficult moving high power electronic load. It saves plenty of room space and solves the space issue when upgrading the electronic load in an automated test system. Moreover, the 63200A provides 4 sets of user-defined hot keys that enable the user to enter the operation mode quickly.

ICONIC FUNCTION SELECTIONS

The iconic function selections make it easier for users to control/operate the 63200A series. The basic and advance functions are iconized, users can select the functions via the rotary or arrow keys. The abbreviations are shown in the icons and the full descriptions are shown on the VFD display for users to easily operate without the need for an operation manual.

FLIPPABLE FRONT PANEL

The 63200A series is equipped with flippable front panel for 7U, 10U & 13U height models with maximum flippable angles 70˚. This design allows convenient access to controls from any height.

APPLICATION OF BASIC LOADS

The 63200A series electronic loads operate in constant voltage, current, resistance, or power modes to satisfy a wide range of test requirements. For instance, the CC and CR modes ensure that the UUT voltage outputs remain stable when the load varies. For battery chargers or charging stations, CV mode can change their output voltage to ensure the precision of the charging current. When the UUT is a battery, the electronic load changes to simulate device loading behavior. Many battery discharge applications and power consumption profiles can be simulated for analysis, making the CP mode the best choice for simulating electronic device loads.

MASTER/SLAVE PARALLEL CONTROL

When the need is for increased power, two or more loads can be run in parallel to achieve the desired load current. The 63200A provides the user with smart Master/ Slave mode controls which enables the user to program the load currents of the Master and have them automatically calculated and downloaded to the slave loads. Using several loads in parallel to emulate a single load dramatically simplifies the operation. All models of the series can be integrated into a 41U standard rack to save space. The 63200A can be controlled and reconfigured with automated testing applications via standard USB or optional Ethernet and GPIB interfaces.

SINE WAVE DYNAMIC LOAD

The 63200A series has a unique sine wave loading function which allows setting of a current bias (I_DC), a loading sine wave (I_AC) and sine wave frequency. The sine wave loading must be greater or equal to zero ampere. This function can be used for D/D, server power supplies and fuel cells for DCIR testing.

DYNAMIC LOAD

Modern electronic devices operate at very high speeds and demand rapid transient response characteristics. To address these applications, the 63200A series offers high speed, programmable dynamic loading (CCD: Dynamic Current Loading & CRD: Dynamic Resistance Loading) and sweep simulation for testing. The figure shown below exhibits the programmable parameters such as current high/low level, T1/T2, rise/fall rate and execution times. When the load current changes continuously, the internal monitoring mechanism and line circuit can minimize the current waveform distortion. The current rise minimum response time for model150V is 10μs and the dynamic change is up to 50kHz.

The dynamic mode provides a unique simulation capability allowing users to set the number of times each cycle repeats from 1~65535. This feature is very suitable for testing D/D converter and instant large withstand current of batteries.

DYNAMIC FREQUENCY SWEEP CONTROL

The 63200A also offers a unique dynamic frequency sweep (as shown on the right) with variable frequencies up to 50kHz. This capability is ideal for determining worst case voltage peaks. Measurement of the Vpeak (+/-) can be achieved using this function with a sampling rate of 500kHz. The dynamic loading mode can simulate different loading conditions for most test requirements. Dedicated remote load sensors and control circuits guarantee minimum waveform distortion during dynamic loading.

CONSTANT IMPEDANCE MODE (CZ MODE)

There are many capacitors on the mainboard of PC. To prevent the inrush current from occurring and trigger the over current protection of server power (since the server power charges the capacitors on the mainboard). It is necessary to test the capacitive loading when turning on the power supply. Therefore, the 63200A series provides the CZ mode for this test.

The unique CZ mode designed in 63200A series can improve the loading behavior of CC & CP mode and makes the simulated loading current more realistic.

ULTRA HIGH PRECISION MEASUREMENT

The 63200A series provides three operating and measuring ranges. Take 63206A-150-600 for example, three voltage ranges of 16V/80V/150V which can meet the requirements of server power or telecom power (12V, 48V, 54V) testing; three current ranges of 60A/300A/600A which can provide different applications of current operating and can minimize the measurement error by selecting the suitable range. Besides, a built-in highly precision A/D converter, achieving 0.015%+0.015%F.S., 0.04%+0.04%F.S. and 0.1%+0.1%F.S. accuracy for voltage, current and power measurement espectively. Precise measurements like these are ideal for testing power efficiency and other critical parameters of the UUT's.

OVER CURRENT & OVER POWER TESTING

To ensure user safety and minimize power supply failure rates, overcurrent and overpower protections have to be taken into consideration during design. The 63200A enables the user to set current and power orders to test overcurrent and overpower protections, also to judge the test result as Pass or Fail on electronic load. The maximum power (Pmax) during testing can be captured and showed on the display without using an oscilloscope to verify the correctness of designed overcurrent and overpower . It can save a lot of testing time for the user.

USER DEFINED WAVEFORMS

In addition to common CC, CV, CP and CR loading modes of conventional loads, the 63200A accepts digital data from DAQ cards or analog data from function generators to allow for complex waveforms to be created as depicted below.

The 63200A also provides an enhanced feature, User Defined Waveform (UDW), to simulate the actual current profiles and waveforms. To reconstruct the actual current waveform, the user can upload captured waveform data into any load via a Chroma softpanel. Each load is capable of storing up to 10 sets of waveforms with each comprising up to 1.5 millions data points to meet the more strenuous test requirements.

In addition, 63200A series also provides voltage peak measurement during actual loading conditions. Avoiding the need for using an oscilloscope to capture the voltage peak, saving time and costs.

BATTERY DISCHARGE TESTING

The 63200A has three discharge modes: CC, CR and CP. The electronic load can set cut off voltage and time (1~100,000 sec.) to stop loading correctly and make sure the battery is not damaged due to over discharge. In addition it can measure the battery discharge power (WH, AH) and total discharge time. For example, when Load ON is pressed, the 63200A internal clock will start counting until the battery voltage is dropped to cut off voltage or Load OFF is pressed. The battery discharge testing can also apply to super capacitor for discharge time testing and so on.

PROGRAMMABLE LOAD TIMING

The 63200A series electronic load has built in 255 programmable timings for various loading conditions simulation. Following lists the applications of common programmed timings.

1. Battery discharge & other applications (NPC, electric car and electric locomotive) to simulate various dynamic loading current waveform, that is to provide two levels above dynamic current simulation or one shot loading simulation.

2. Server/ Telecom power supply mixed load modulation. (For multi channels output UUT.)

DIGITIZING FUNCTION

The 63200A series offers a digitizing function convenient for the recording of transients in both voltage and current waveforms. The following are the specifications for setting the parameters:

Sampling time:2μs ~ 40ms / resolution: 2μs (Setting the interval of sampling time)

Sampling point:1 ~ 15,000 (Setting the total sampling points)

COMPLEX OPERATING MODE

New complex operating modes include CR+CC, CV+CR and CV+CC modes. The CR+CC mode is suitable for power on testing and the CV+CR mode can replace Von setting while the CV+CC mode can be used for battery discharge testing.

AUTO MODE

This mode automatically switches among CV, CR, CC and CP modes. It is suitable for lithium ion battery charger testing to get a complete V-I charging curve. Moreover, the auto mode can avoid damaging the UUT when the protection circuit is damaged.

SOFTPANEL

The 63200A series loads can be operated from the front panel controls or from available softpanel. This user friendly software includes all functions of the 63200A series loads and is easy to understand and operate. The 63200A loads can be controlled via GPIB, USB and Ethernet interfaces for remote control and automated testing applications.

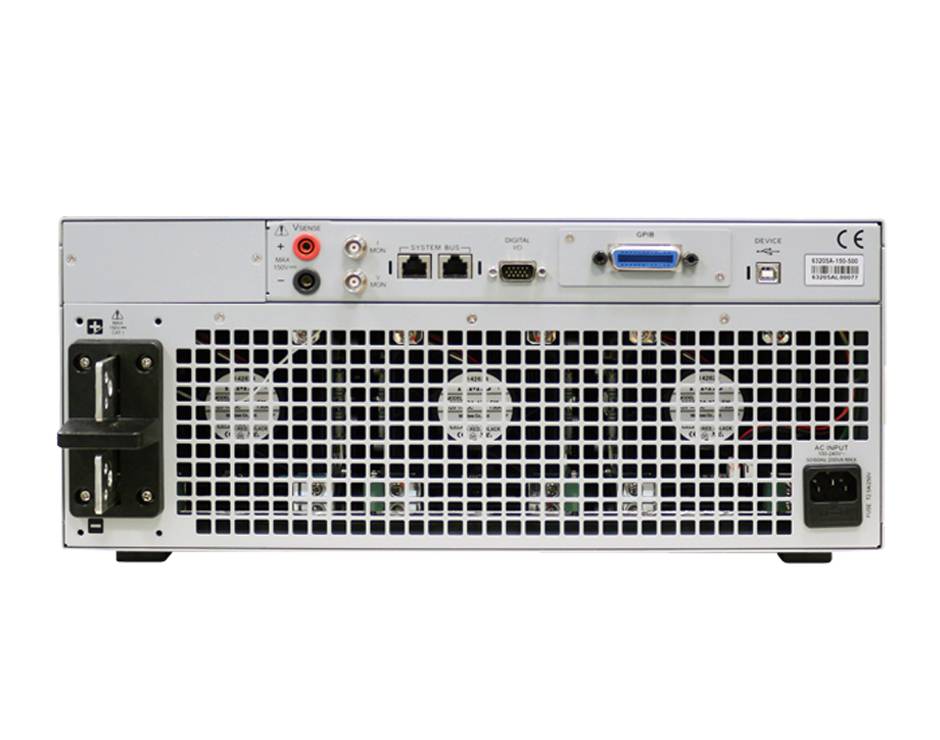

PANEL DESCRIPTION

1. Power Switch : Electronic load AC power switch

2. Vacuum Fluorescent Display : Setup information display

3. Shortcut Keys : Loading mode switch

4. Function Keys : Including A/B key, RANGE, MODE, EXTEND, LOCK, COFIG./LOCAL, EDIT, SPEC, SHORT, RECALL, ADVA, SAVE & CLEAR

5. ENTRY Keys : Numerical keys and ENTER key

6. Arrow Keys : Changing and selecting menu

7. Push-on Knob : Editing parameter setup page, push the knob again to confirm the input value when the setting is done

8. USB Host (not ready yet) : For user defined waveform and programmed sequence data download as well as firmware upgrade

9. Load Positive/Negative Terminal

10. Remote Sense Connections

11. Analog Outputs : Proportional voltage and current waveforms

12. System BUS : For master/slave system data transmission

13. System I/O : For system input/output signal control

14. GPIB & Ethernet Card Slot

15. USB Port

16. AC Input Connector

High Power Application

![]() Request for quote. Please Select the items and "Add to Inquiry Cart".

Request for quote. Please Select the items and "Add to Inquiry Cart".

Ý kiến bạn đọc

- NGOC MINH ISE CO.,ltd (NGOC MINH ISE CO.,ltd)

- Địa chỉ: Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City; Ho Chi Minh Office: Bock A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc District, HCMC

- Điện thoại: +84-28-66865303 +84982427168

- Fax: +84-28-66865303

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com