-

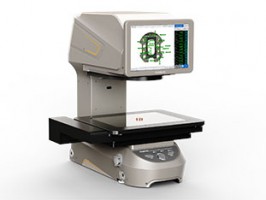

Battery Cell Insulation Tester Model 11210

- Post on 27-03-2019 09:34:48 AM - 6336 Views

-

Chroma 11210 battery cell insulation tester is an instrument used for accurately measuring leakage current (LC) and insulation resistance (IR) of battery jelly-roll/dry-cell as well as various insulation materials. In addition to standard LC/IR measurement, the 11210 has a unique function that detects partial discharge (PD) or flashover that may have occurred inside the insulation material during the high voltage insulation testing process. With PD detection of the battery's internal status before electrolyte filling, defective products can be filtered out before entering the next stage of production preventing the potential hazards that may occur in the field. In contrast to traditional methods of insulation test, Chroma 11210 provides an entirely new concept for inspection and evaluation of battery quality.

Key Features:

- Test voltage: up to 1KV(dc)

- Charge current: 50mA max.

- Wide range of Leakage Current (LC) measurement (10pA ~ 20mA)

- Partial discharge/flashover detection for inspection on potential internal short circuits (option of A112100):

- PD level and number of occurrence display

- PD events and V/I waveform monitor

- Programmable PD level limit setting

- PD and V/I waveform logging (option of A112101) - Built-in reliable contact check

- Automatic test with sequence: charge-dwell-measure-discharge

- High speed testing (20ms/device)

- 480x272 pixels full-color display and touch panel for easy operations

- Standard Handler, USB, RS-232, Ethernet interfaces

Chroma 11210 battery cell insulation tester is an instrument used for accurately measuring leakage current (LC) and insulation resistance (IR) of battery jelly-roll/dry-cell as well as various insulation materials. In addition to standard LC/IR measurement, the 11210 has a unique function that detects partial discharge (PD) or flashover that may have occurred inside the insulation material during the high voltage insulation testing process. With PD detection of the battery's internal status before electrolyte filling, defective products can be filtered out before entering the next stage of production preventing the potential hazards that may occur in the field. In contrast to traditional methods of insulation test, Chroma 11210 provides an entirely new concept for inspection and evaluation of battery quality.

With an ample charging current capability, the 11210 can easily achieve high speed testing with automatic execution of the test sequence. The sequence of a regular insulation test in the target application is "Charge→Dwell→Test→Discharge" This sequence can be automatically executed in 20ms or less for a single DUT (Device Under Test); meaning tests performed in the production line can achieve process rates of 50 pcs/sec or more.

Chroma 11210 measures the LC in a wide range, from 10pA to 20mA with 7 ranges of current measurement to enhance the accuracy. The auto-range function is also available for quick and easy operations on a new DUT.

Due to special circuitry used in the Chroma 11210, no extra time is required for the PD detection function. Both LC/IR measurements and PD detection tests can be performed simultaneously and both test results will be reported automatically. Thus, high speed testing at <20ms per DUT is achievable even when both LC/IR and PD tests are being performed.

In a traditional insulation test, contact checking is critical to the reliability of a complete test. No-contact on the DUT is very likely treated as a "pass" during the test, while the real insulation test has not been executed on that DUT yet. Thus, a "falsegood" condition could occur and a defective DUT may be passed as good. This is especially true if the insulation resistance of the DUT is extremely high. The contact check function in the Chroma 11210 employs advanced technology to instantly detect those which do not make secure contacts during the tests. It takes only 5ms to do a thorough contact check before and/or after the measurement.

SAFETY ISSUES OF LITHIUM ION BATTERY

Consequences from fire or explosion of lithium ion batteries (LIB) is an increasing concern. As technology advances, the energy density of the LIB increases posing a further risk to consumers. In order to eliminate the risk of fire or explosion, the root cause must be resolved and the defective units must be filtered out before they reach the consumer market. Recent research indicates that internal short circuits between the positive electrode (aluminum) and the material coated on the negative electrode (anode) inside the cell is the root cause of the fire or explosion [Figure 1]. Burrs on the metal electrodes or contaminated particles inside the separator can cause this kind of internal short circuit. [Figure 2].

The research also shows that the material coated on the negative electrode (typically graphite) would expand during the charging phase, expanding up to 24% or more as the charge/discharge cycle repeats. It could continue to expand until the burrs on the aluminum plate finally touch the graphite coated on the negative electrode and result in fire disaster [Figure 3]. There are usually several charge/discharge cycles carried out on the battery cells in the factory before shipping. Let's take an example, two cases of defective cells are present in the production line, and each has a single burr with different height or length on its aluminum plate [case 1 & case 2 in Figure 4]. Case 1 will be detected at the second charging cycle in the factory, since the burr touches to the anode then. However, in most cases, the second one will not be detected until many more charging cycles later, which is very likely to happen after it reaches the consumer.

PD DETECTION AND MEASUREMENT FUNCTION

The Partial Discharge (PD) detection function of Chroma 11210 has the ability to detect those defects inside the battery cells in the dry cell stage prior to electrolyte filling. When there are burrs on the electrode metal sheet or defects (impurity particles) inside the insulation layer (the separator sheet) in the dry cells, the insulation distance left between them is shortened but not shorted. In most cases, they cannot be detected by regular insulation LC/IR tests, since the internal short circuit does not exist at the time of executing the tests. The 11210 is the only instrument that can help you to detect possible shorts in the very early phase before any failures can occur. With the proper test voltage applied and the proper PD threshold level set, the 11210 can help you to "measure" the "effective distance" left between the negative electrode and the graphite material (see equation and explanation on the right).

Chroma 11210 battery cell insulation tester detects any PD or flashover that may occur inside the battery cells. There are two phases of detection that the 11210 employs with different circuitries used. The first phase is in CC (Constant Current) mode when the 11210 charges the DUT with a constant current set by the user. During this mode, the 11210 will monitor the voltage level and its slope. Any glitches on the voltage slope or any unexpected changes of the slope will be detected by the 11210 and reported as PD occurrences (shown as ). The second phase is in CV (Constant Voltage) mode. In this mode, only a stable leakage current should exist. Thus any unusual and protruding pulses on the current waveform are typically the result of an abnormal discharge (i.e. PD or flashover) which will also be detected and reported by the 11210 as a PD occurrence (shown as

). Chroma 11210 not only detects, but also roughly measures the magnitude of the PD pulses during these modes (Note *1). [Refer to Figure 5 for illustration].

|

| ▲[Figure 5] PD/Flashover detection in both the CC (charging) & CV (measurement) phase |

|

| ▲[Figure 6] PD detected in CC & CV mode and reported by 11210 |

Whether in CC mode or CV mode, the 11210 is able to detect the number of occurrences of those PD events, up to 99 counts [Figure 6]. Either the magnitude or the number of occurrences or both can be set as a threshold level for pass/fail criteria, which is very helpful when testing various devices with different characteristics in the production line.

Note *1 : The measurement of discharge quantity in PD pulses is most accurate when pulse duration is shorter than 100us, and the time interval between consecutive pulses is larger than 300us.

Due to superior PD detection and measurement capabilities, Chroma 11210 can accomplish tasks that a regular LC/IR meter or a hipot tester cannot. A regular LC/IR meter or hipot tester is only able to measure the average value of the leakage current within a certain time interval, but is not able to monitor every detail in the voltage and current waveform. Furthermore, the 11210 provides ultra-stable test voltage with ripple and noise of some mini-volt only, which enables it to look for very minor glitches on the voltage or current waveform. [Figure 8] shows you that without looking into the details of the voltage waveform, minor PD or flashover inside the DUT cannot be detected.

|

| ▲[Figure 7] Without looking into the details of the voltage waveform (left picture), you see nothing abnormal. With Chroma 11210 looking into the details, we can observe two PD events occurred, one in CC mode, the other in nearby CV mode (right picture). |

In case the engineering staff needs to review the actual voltage and current waveform on a failed DUT (failure due to PD) after tests are completed, Chroma 11210 offers an advanced option that can store both voltage and current waveforms from each individual device's test. Zooming functions allow users to view waveform details of the PD events easily. And since they are captured and recorded, additional analysis and research can be performed by R&D and/or QA departments.

CAPACITOR TEST APPLICATIONS WITH 11210

Chroma 11210 is the next generation and advanced version of its predecessor the 11200 capacitor LC/IR meter. The 11210 includes more versatile functions with higher accuracy, however, retains all the major functions and capabilities found in the 11200. Therefore, the 11210 is also an advanced LC/IR meter for all types of capacitors [Figure 8].

|

| ▲[Figure 8] Block diagram of LC/IR measurement test by 11210 for the DUT of capacitors |

In the production line, the 11210 is able to test capacitors at a very high speed (~20ms per DUT) with appropriate fixtures. Moreover, it has a very wide range of LC/IR measurement with excellent accuracy. Chroma 11210 is the new standard insulation inspection and test instrument for all capacitor production lines.

Though the PD detection function is specifically designed for the insulation inspection of battery dry cell, it also provides a clear picture of what's going on inside a capacitor during the tests. And with the data collected from the 11210, users can further enhance or improve the insulation quality ensuring the highest quality of insulation is achieved.

As mentioned previously, in a typical insulation test, 4 phases are executed in sequence, which are "Charge→Dwell→Test→Discharge" [Figure 9]. Chroma 11210 allows the users to program the time interval required for the first 3 phases respectively. Each can be set in the range of 5ms to 9.999sec. The phase of "Dwell" is particularly important. For large and pure resistive devices or capacitors with large capacitance but low insulation resistance, the user must allow sufficient "Dwell" time before the actual measurement takes place. The long "Dwell" time is necessary to let the charging current settle down so that it will not affect the leakage current measurement. The 11210 is extremely flexible in these parameters programming, and is able to execute those 4 phases in sequence automatically. For capacitor production testing, Chroma has the knowledge and technologies to assist customers in setting up a reliable inline test or provide a complete turnkey test solution.

|

| ▲[Figure 9] Timing & sequence of the regular insulation test |

![]() Request for quote. Please Select the items and "Add to Inquiry Cart".

Request for quote. Please Select the items and "Add to Inquiry Cart".

-

Unparalleled Stability...

27-03-2019 01:38:04 AM -

The Reference Machine in...

27-03-2019 01:28:20 AM -

SMALL PARTS COUNTER U-60

27-03-2019 01:04:31 AM

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com