-

Battery Cell Charge/Discharge Test System Model 17011

- Post on 27-03-2019 09:33:26 AM - 4358 Views

-

The Chroma 17011 Battery Cell Charge and Discharge Test System is a high precision system designed specifically for testing lithium-ion battery (LIB) cells, electrical double layer capacitors (EDLC), and lithiumion capacitors (LIC). It is suitable for product development, quality control, and helpful to characteristic research, cycle life testing, product screening, and quality assessment.

Key Features:

- High precision output and measurement up to 0.02% of F.S.

- Fast current response up to <100 μS

- High sampling rate up to 10 mS

- Flexible sampling recording (Δt, ΔV, ΔI, ΔQ, ΔE)

- Channel parallel output function with maximum 1200A output

- High efficiency charge and discharge with low heat

- Energy recycling during discharge (AC/DC bi-directional regenerative series)

- Waveform simulation function (current/power mode)

- Built-in DCIR test function

- Built-in HPPC test function

- Built-in EDLC capacitance and DCR test function

- Operating modes: CC / CP / CV / CR / CC-CV / CP-CV / Rest / SD test

- Multi-level safety protection mechanism

- Integrating data logger and chamber

Applications:

- Electric vehicle

- Electric scooter/bike

- Energy storage system

- Power tools

- Quality inspection agency

- Academic research

The Chroma 17011 Battery Cell Charge and Discharge Test System is a high precision system designed specifically for testing lithium-ion battery (LIB) cells, electrical double layer capacitors (EDLC), and lithiumion capacitors (LIC). It is suitable for product development, quality control, and helpful to characteristic research, cycle life testing, product screening, and quality assessment.

The Chroma 17011 has developed linear circuit and regenerative AC/DC bidirectional test systems for different applications. The linear circuit test system featured in extremely low output noise and high measurement accuracy is suitable for testing energy storage components in small and medium sizes. The regenerative bidirectional test system with high efficiency, power saving, low heat, and stable measurement capabilities is applicable for testing energy storage components in medium and large size or power type battery cells to meet the low carbon emission production for the green energy industry.

In addition to the commonly used constant current (CC), constant power (CP), constant voltage (CV), constant resistance (CR), and rest test modes, Chroma 17011 is also equipped with waveform simulation functions and test items including DCIR, HPPC, EDLC capacitance, and EDLC DCR to comply with the international standards that made the programs editing and test results analysis much easier.

The Chroma 17011 test system has flexible software editing functions embedded that can create basic charging/discharging or complex cycle tests for each channel to run independently. The program can edit logic decisions to jump or output variables, and pause or resume. It also has data protection function to securely store the data in a nonvolatile memory in case of a power outage or disconnected communication to prevent potential data loss and resume the tests after reboot.

Since safety is very important for testing lithium-ion battery cells, the design of Chroma 17011 offers a variety of safety protections such as performing contact check and polarity check before the test starts to avoid testing under poor connection. Besides the intrinsic hardware circuit protection, the user can customize the firmware to detect overvoltage (OVP), over current (OCP), over capacity (OQP), voltage / current variation (ΔV / ΔI), loop resistance and other abnormal conditions to safeguard the lithium-ion battery cells.

LINEAR CIRCUIT TEST SYSTEMS

High precision – improving product quality

- Voltage / current measurement accuracy: ±0.015% of F.S. / ±0.02% of F.S.

- Multiple range measurement design: Provide multiple current or voltage ranges based the models to greatly improve the measurement accuracy and resolution. The current range switches automatically without any current output interruption at constant voltage mode.

Fast current response – suitable for a variety of high-speed transient test applications

- Current response speed (10% to 90%) < 100 μS*

- Support dynamic waveform to simulate the rapid changing current and power states

| * Note: The current response speed of model 17216M-10-6 is <100 μS, also the impedance of UUT may different slightly. |

High frequency sampling measurement technology – improving measurement accuracy

- V / I sampling rate: 50 KHz (Δt:20 μS)

Generally, battery tester use software to read current values for calculating power. However, limited data sampling rates could result in large errors when calculating the dynamic current capacity. By increasing the sampling rate and using a double integration method, Chroma 17011 is able to provide a capacity calculation with much higher accuracy. When the current changes, the data is not lost and the transmission speed is not affected.

REGENERATIVE BIDIRECTIONAL TEST SYSTEMS

Energy recycling – optimal utilization of electricity

- Direct recycling: Automatically transfer the discharging energy to the battery cell to be charged with recycling efficiency >80%

- Grid recycling: Recycle the excessive energy to the grid with recycling efficiency >65%

- Implementation of low carbon emissions for green energy to prevent waste heat from generating during discharge

- Saving electricity costs with high efficiency power charge and discharge

- Saving air conditioning costs on cooling equipment

- Total harmonic distortion <5% for equipment feedback to grid current

- Power factor >0.9 at rated power

High precision – improving product quality

- Voltage accuracy: ±(0.02% of Reading + 0.02% of F.S.)

- Current accuracy: ±(0.05% of Reading + 0.05% of F.S.)

Fast current response – waveform mode

- Current response speed (10% to 90%) < 10 mS applicable for all kinds of tests

- Support dynamic waveform to simulate the current and power state of actual driving with NEDC, FUDS and DST test standards

DYNAMIC WAVEFORM SIMULATION

- Simulate dynamic charge/discharge waveform of actual battery usage. In the dynamic urrent mode (waveform), the fastest switching time of maximum discharge and charge current is 10 mS

- Import the current and power waveforms from Excel file

- Save 720,000 points in each channel for long hour dynamic testing

- Minimalize time interval for data output: 10 mS

FLEXIBLE PARALLELING CHANNELS FOR OUTPUT

The test system allows flexible setting for paralleling channels to provide higher urrent application for multi-channels and broad testing ranges, which are suitable for numerous UUTs.

- Easy to parallel the tester channels via software which supports full range of products

- Suitable for high ratio charge and discharge test or diversified battery test applications

BATTERY DCIR TEST APPLICATION

The internal resistance value is related to the charge/discharge ratio of a battery. The larger the internal resistance value, the lower the efficiency when temperature rises. According to the lithium-ion battery equivalent circuit model, the ACIR measurement of traditional 1KHz LCR meter can only evaluate the conductive resistance (Ro) of the battery that affects the instantaneous power output, but unable to evaluate the polarization resistance (Rp) caused during electrochemical reaction. The DCIR evaluation includes the ACIR that is closer to the actual polarization effect of battery under continuous power applications.

BATTERY CAPACITY TEST APPLICATION

The capacity can be obtained by integrating the current with respect to time from starting charging and discharging to the end of cut-off condition. The comparison results can be used to analyze the performance of a product, and the common test items include current ratio and temperature characteristics tests. The higher accuracy of current, voltage measurement and the faster of sampling can more accurately distinguish the difference of battery cell capacity.

BATTERY CYCLE LIFE TEST APPLICATION

Cycle life is one of the most important test items for batteries. In accordance with the experimental purpose, it tests the same battery through repeated charge and discharge conditions until the capacity falls to 80%, and calculates the cycle numbers. The cycle life test can be used to evaluate the battery performance or define the applicable conditions.

COULOMBIC EFFICIENCY TEST APPLICATION

Coulombic efficiency is calculated by the ratio between charge and discharge capacity when the battery is fully charged and discharged. A good battery has higher coulombic efficiency, and needs high precision and stable equipment to distinguish the differences. An accurate coulombic efficiency test can

estimate the battery lifespan with a few cycles.

INCREMENTAL CAPACITY ANALYSIS APPLICATION

The high-precision voltage measurement and ΔV sampling function can draw dQ/dV vs voltage curve diagrams for bat tery cel l character i s t ics and capaci ty degradat ion analysis.

HPPC TEST APPLICATION

HPPC is a test solution created by the USABC (U.S. Advanced Battery Consortium) that tests the battery power performance of hybrid and electric vehicles. The main purpose of the test is to establish the function of the relationship between the depth of discharge and power within the batteries operation voltage range, with the secondary purpose of establishing the depth of discharge, conductive resistance and polarization resistance function via the voltage and current response curve from discharging, standing to charging within the battery voltage range. The measured resistance can be used to assess the power recession of the following life test and the equivalent circuit model development of power battery. The user can automatically obtain the test results that comply with the HPPC standards without any manual calculation.

EDLC TEST APPLICATION

EDLC capacitance testing

According to the EDLC testing standard IEC 62391, the EDLC has to be CV charged before testing the capacity. The capacity test is to discharge CC via the above discharge current. Then, get the EDLC voltage difference, time interval and discharge current to calculate the EDLC capacity.

EDLC internal resistance (DCR) testing

According to the EDLC DCR test standard IEC 62391, the EDLC has to be CV charged before testing the capacity. The capacity test is to discharge CC via the above discharge current. When the discharge is done, get the linear section on the discharge curve and extend it to discharge time and then get the voltage difference of rated voltage and discharge current to calculate the DCR value.

GRAPHICAL SOFTWARE OPERATING INTERFACE

The Chroma 17011 test system is controlled by computer software with diverse functions for testing energy storage products. It has high safety, stability and friendly operation interface allowing users to perform setting and testing rapidly.

- Support Traditional Chinese, Simplified Chinese and English three languages interface

- Real time system status monitoring

- Security management: Able to set user authority for management

- Failure record tracking: Independent channel to record abnormality, charge and discharge protection will abort the test when an abnormal condition is detected

Recipe editing

- 500 steps per recipe

- Double loop (Cycle & Loop) with 999,999 repeat counts per loop

- Sub-recipe function: Call existing recipes

- Test step: CC / CV / CP / CC-CV / CP-CV / CR / Rest / Waveform / DCIR / C / DCR, etc.

- Cut-off condition: Time / Current / Capacity / Power / Variable, etc.

- Logical operation: Next / End / Jump / If - Then

Statistics report

- Able to define report format to export PDF, CSV and XLS files

- Graphical report analysis function: Custom reports such as cycle life reports, Q-V reports, V / I / T time reports, etc. are allowed.

SYSTEM INTEGRATION

- Integrating with environmental chamber through software can do sync settings conditions for charge/discharge testing

- Integrating with multifunctional data logger through software can read multiple temperature records during charge/ discharge process, and the conditions can turn to protection or cut-off conditions

- Integrating with ACIR test fixture through software can measure the ACIR in rotation when the 1KHz ACIR test switch fixture is in use

PC EXCEPTION ALLOWED

-

Maintaining operation: When error occurs on PC or the connection is interrupted during testing, if the 17011 power is not out, the test will continue and save the data in memory. Restore PC connection before the memory is depleted and the data can be retrieved to maintain operation.

-

Test recovery: If the entire factory is having power outage, the 17011 will save the executed commands in memory and restart after the problem is solved. When the PC receives the commands, it can choose to resume the test step stopped at power outage or to start the testing again.

TEST SYSTEM CONFIGURATION

Linear circuit models | | Regenerative models |

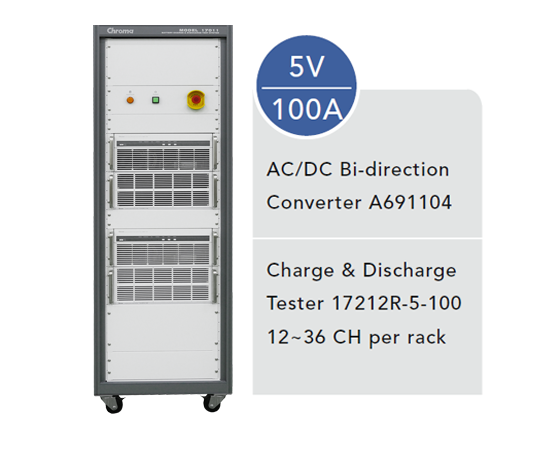

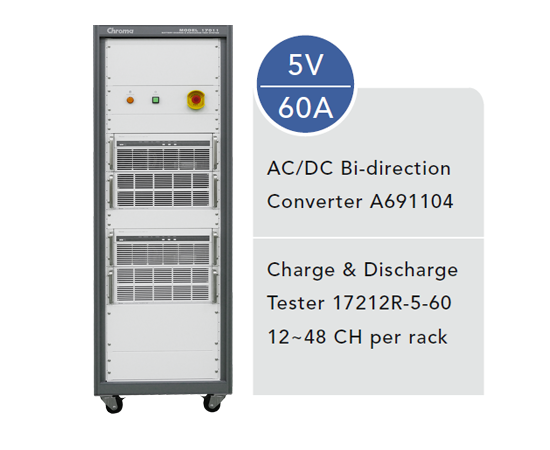

| The tester can be used standalone in a small space, which is suitable for a handful of tests performed on the desktop. When the tester is configured with many test channels, it can be integrated into a standard 19 inch rack for use. The system can be configured as demanded by the user as the channel numbers are expandable, and up to 64 channels can be controlled at the same time. | A charge/discharge tester and an AC/DC bi-direction converter can integrate into a standard 19 in. rack for use. The system can be configured as demanded by the user as the channel numbers are expandable, and up to 48 channels can be controlled by a PC at the same time. |

![]() Request for quote. Please Select the items and "Add to Inquiry Cart".

Request for quote. Please Select the items and "Add to Inquiry Cart".

-

Unparalleled Stability...

27-03-2019 01:38:04 AM -

The Reference Machine in...

27-03-2019 01:28:20 AM -

SMALL PARTS COUNTER U-60

27-03-2019 01:04:31 AM

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com