Post on 27-03-2019 01:38:04 PM

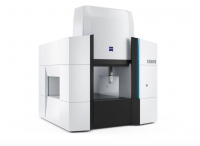

A measuring machine for production

ZEISS CenterMax can be directly integrated into a production line. Vibrations from processing centers are effectively damped. Its variable workpiece base makes it ideal for automated loading.

Post on 27-03-2019 01:36:36 PM

Measurements with enormous speed and precision

ZEISS GageMax measures directly in production and is unaffected by extreme temperature fluctuations and ground vibrations. This measuring machine can also measure unknown curves and freeforms via active scanning.

Post on 27-03-2019 01:35:07 PM

No need for fixed gauges

ZEISS DuraMax eliminates the need for fixed gauges. Equipped with the VAST XXT scanning sensor from ZEISS, it can even be used to capture contours and freeform surfaces. A rough production environment? No match for ZEISS DuraMax.

Post on 27-03-2019 01:33:16 PM

High-end measuring machine for maximum precision

ZEISS XENOS is at home wherever maximum precision is demanded – in the measuring labs of research institutes, the aerospace industry and the optical industry. The high-end machine combines precision at the limits of what is technically feasible with a measuring range of nearly one cubic meter.

Post on 27-03-2019 01:31:12 PM

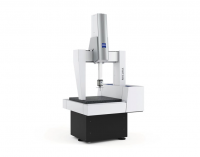

High-speed scanning and maximum accuracy

PRISMO from ZEISS is synonymous around the world for high-speed scanning and maximum accuracy in the measuring lab and near production. With length measurement error of just 0.5+L/500 micrometer, ZEISS PRISMO ultra is ideal when maximum demands on precision have to be met.

Post on 27-03-2019 01:29:57 PM

The future-proof bridge-type measuring machine

Are performance and precision your top priorities? With its wide range of configurations, the ZEISS ACCURA measuring machine can be tailored to your needs – and budget.

Post on 27-03-2019 01:28:20 PM

For reliable and uncompromising quality assurance

The latest generation is even more precise and offers a large package of optical sensors on top of a larger measuring range.

Post on 27-03-2019 01:26:02 PM

No compromises when it comes to accuracy

Despite its small size, ZEISS MICURA makes no compromises when it comes to accuracy. ZEISS MICURA comes standard with the VAST XT gold scanning sensor from ZEISS and navigator technology.

Post on 27-03-2019 01:23:47 PM

Your company's production plan needs to be fullfilled? Growth ratios performed? No time for complaints and lowered productivity - caused by missed error detection of defective parts?

With the new ZEISS SPECTRUM you will enter the next level of certainty and productivity. Trust your parts due to more reliability in the measurement results. Upgrade to trusted measuring results.

Post on 27-03-2019 01:15:54 PM

The digital measuring projector for reliable optical measurements

Thanks to fully automatic setting of both illumination and focus, measuring errors due to operator influence are eliminated. At the mere push of a button, ZEISS O-SELECT evaluates the characteristics and documents the results – also in a professional report if needed.

Post on 27-03-2019 01:13:32 PM

An expert in every discipline

ZEISS O-INSPECT multi-sensor measuring machines enable to optimally measure each characteristic – optically or by contact.

-

Unparalleled Stability...

27-03-2019 01:38:04 AM -

The Reference Machine in...

27-03-2019 01:28:20 AM -

SMALL PARTS COUNTER U-60

27-03-2019 01:04:31 AM

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com