-

Highlights Reflow System Ersa HOTFLOW 4/26

- Post on 27-03-2019 02:59:28 AM - 4240 Views

-

- Reflow soldering system with outstanding thermal performance and an excellent power balance

- Individually controllable process zones via energy-optimized motors

- Multi-level controlled cooling

- Multi-level process gas cleaning with pyrolysis

- Rest-oxygen monitoring and control, low N2 consumption

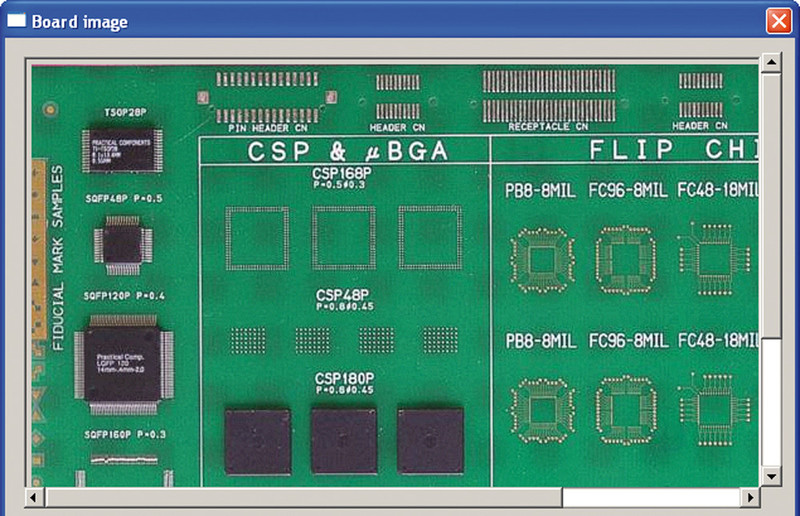

- Ersa Process Control software (EPC)

- Software to generate temperature profiles

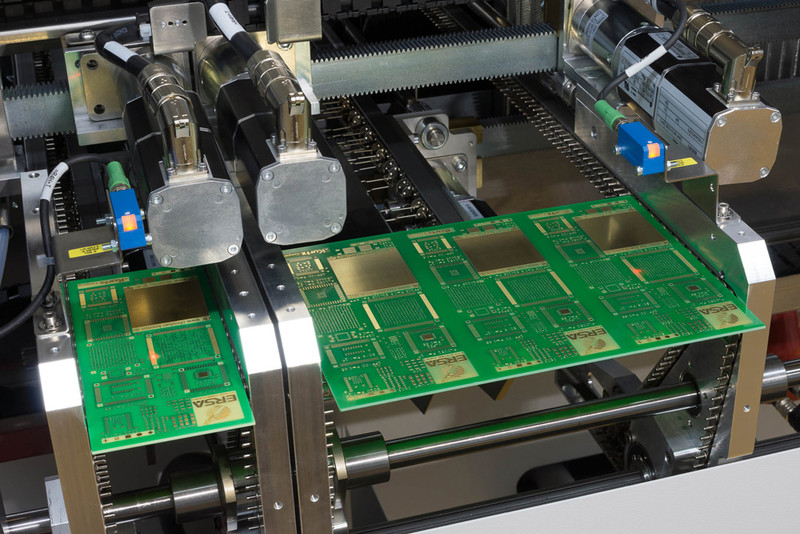

- Multi-track conveyor systems (1-4), 1x fixed, 3x variable

- Thermally invisible center supports

- Low energy consumption in continuous operation

- Patented grip conveyor system for flex boards

- Auto Profiler to off-line and quickly generate temperature profile

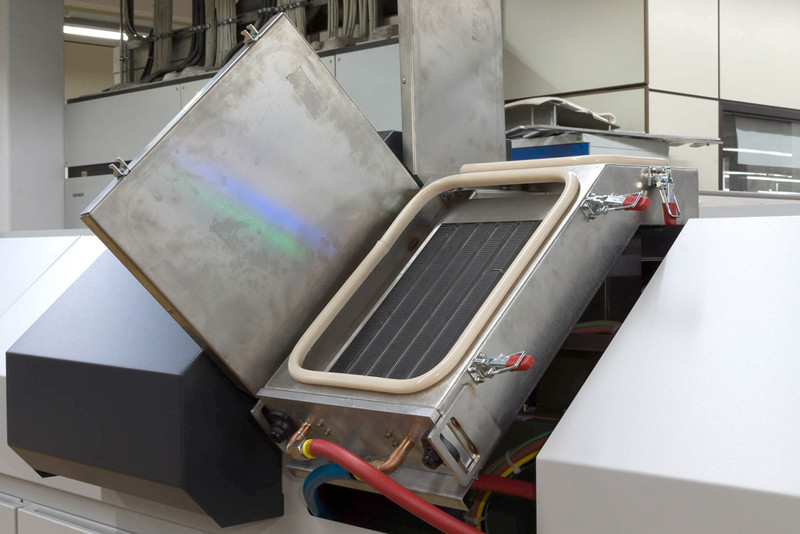

The Ersa HOTFLOW 4/26 Reflow Soldering System is of robust design and manufactured entirely from steel, welded air-tight, powder coated and with interior electric cabinet and a PC operating terminal. Features include the motorized hood opening, quick-change convection heater cassettes, multi-level process gas cleaning and a powerful and a high-performance cooling zone.

Dimensions

- Length: 7,705 mm

- Width: 1,410 mm

- Height: 1,350 mm

- Weight appr. 2,800 kg

Conveyor system

Process zone

Heating system

Cooling

Electrical data

Exhaust

- Pin-and-chain conveyor with either 3 / 4 / 5 mm pin length

- Pin-and-chain conveyor with low-mass center support

- Motorized adjustment of conveyor width and center support

- Up to 4 tracks with center support in the system (1x fixed, 3x variable)

- Patented grip conveyor system for flex boards

- With single track systems, the use of low mass tubular supports is possible

- Operation with either ambient air or nitrogen

- The cooling zone of the system can be equipped with an integrated cooling system and an external cooling aggregate

- Cooling can be either with cooling aggregate or with local water connection

- Multi-level condensation management system available with pyrolysis

- Heating and cooling cassettes removable without tools

- Energy-consumption management

Keyword:

an excellent,

reflow soldering,

system with,

outstanding thermal,

performance and,

power balance,

individually controllable,

process zones,

via energy-optimized,

motors multi-level,

controlled cooling,

multi-level process,

gas cleaning,

with pyrolysis,

rest-oxygen monitoring,

and control,

low n2,

consumption ersa,

process control,

software epc

Products in this Category

Recently Viewed Products

-

Unparalleled Stability...

27-03-2019 01:38:04 AM -

The Reference Machine in...

27-03-2019 01:28:20 AM -

SMALL PARTS COUNTER U-60

27-03-2019 01:04:31 AM

NGOC MINH ISE CO.,LTD

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com

You did not use the site, Click here to remain logged. Timeout: 60 second