-

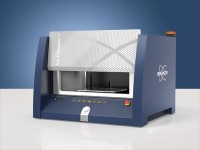

M4 Tornado Plus

- Post on 26-03-2019 11:45:24 PM - 6267 Views

-

A New Era in Micro-XRF

M4 TORNADOPLUS is the world's first Micro-XRF spectrometer that enables the detection and analysis of the entire element range from carbon to americium. As the latest member of the proven, market leading family of M4 TORNADO Micro-XRF analyzers, the M4 TORNADOPLUS also offers additional unique features, such as an innovative aperture management system, an ultra-high throughput pulse processor and a flexible quick-change sample stage.

Super Light Element Detection - seeing down to carbon

Using two large-area silicon drift detectors with super light element window and a specifically optimized Rh X-ray tube, the M4 TORNADOPLUS is the first Micro-XRF spectrometer ever to enable the analysis of light elements. Unlike common Micro-XRF systems, which are suitable to detect elements from sodium up, the M4 TORNADOPLUS allows to also measure elements with atomic numbers Z<11, such as fluorine, oxygen, nitrogen and carbon, without compromising the performance and sensitivity in the higher energy ranges. With this performance enhancement, new applications are opening up for Micro-XRF, e.g. in geoscience and mining, biology, polymer research or semiconductor industry.

Twice the Throughput - for faster measurements

Already the previous dual detector versions of the M4 TORNADO have been trendsetting in this regard, providing up to 260 kcps output count rate with excellent energy resolution. With its unique ability to process up to 1,200 kcps and to deliver an output count rate of up to 550 kcps, the M4 TORNADOPLUS pushes these limits significantly further, enabling unmatched acquisition speed and productivity.

Aperture Management System (AMS) - for better depth of field and resolution

Many specimens to be investigated using Micro-XRF have topographic surfaces, rather than being perfectly flat. Therefore, just like in photography, the depth of field becomes an important parameter for the X-ray optical system used to generate the small excitation spot on the sample surface. Usually, in Micro-XRF analyzers with high spatial resolution X-ray optics (7 µm), the working distance needs to be as small as 2 µm and the achievable depth of filed is less than 1 mm.

The innovative, software-controlled aperture management system (AMS) of the M4 TORNADOPLUS enables a working distance of approx. 9 mm and provides a depth of field of up to approx. 5 mm. That means, the spatial resolution does not get lost, and sample features are kept in focus, even if the sample surface varies over several millimeters. This makes the M4 TORNADOPLUS the instrument of choice for the analysis of specimens with strong topography, e.g. in electronics, forensics, or geoscience.

Quick Sample Exchange - for easier, quicker and more secure sample handling

The M4 TORNADOPLUS also offers a quick-change stage interface and optional special drill core and thin section carriers. These accessories allow the specimens to be placed and fixed quickly and securely onto a removable stage plate and make it easy to attach or exchange specimens for a faster and more secure analysis as well as reanalysis. This saves time both in specimen exchange as well as in measurement set-up, as the specimens will always be at the same height and position.

M4 TORNADO PLUS: Super Light Element Micro-XRF Spectrometer

Second X-ray Tube Collimator Changer - more flexibility when analyzing high-energy lines

The optional second fine focus X-ray tube of the new M4 TORNADOPLUS is equipped with a fully software controlled four-position collimator changer, expanding the flexibility of the spot size from 500 µm to 4.5 mm. This allows either a small collimated spot albeit with lower intensity, or a large high intensity spor for close to common XRF analysis. The result is more flexibility when analyzing larger structures or working with high-energy X-ray lines.

Multi-Functional Computer-Controlled He-Purge - analyze light elements without vacuum

For certain specimens, measurement under vacuum poses an issue because they are sensitive to pressure variation or may dry out. Even though working at ambient air is always possible, X-ray fluorescence from the light elements below Ca is strongly attenuated or even completely absorbed. In order to detect light and super light elements down to carbon also in vacuum-sensitive samples, the M4 TORNADOPLUS offers an optional, computer-controlled He-purge system to extend the analysis range under atmospheric pressure. Two different purging modes can be employed, depending on the specific analytical requirements. For a quick single or multi-point analysis, local high-flow purging of the measurement position is sufficient to reliably acquire the low energy X-rays.

Technical Specifications

| Sample types | Solids, particles, liquids | ||

| Sample chamber size | WxDxH: 600 mm x 350 mm x 260 mm | ||

| Stage | WxD: 330 mm x 170 mm, Max. weight load: 7 kg | ||

| Measurement media | Air or oil free vacuum, 20 mbar in 2 min, optional He-purge system | ||

| Sample travel Max. travel Mapping travel Travel speed | WxDxH: 200 mm x 160 mm x 120 mm WxD: 190 mm x 160 mm Up to 100 mm/s with TurboSpeed stage | ||

| Sample view | 2 simultaneous live images from above with different magnifications for sample overview and precise positioning Lateral fisheye camera for the sample chamber overview | ||

| Excitation | High brilliance, light element X-ray tube with polycapillary X-ray optics and aperture management system (AMS) Optional: 2nd tube with four position collimator changer from 0.5 to 4.5 mm | ||

| Excitation parameters Target material Tube parameters Spot size AMS filters Filters | Rh, optionally Ag (light element), fine focus: Rh, W, Mo, Cu, Cr 50 kV, 30 W (40 W for collimator) Less than 20 µm for Mo Kα (17.5 keV) with polycapillary lens 500 µm and 1 mm apertures, plus 6 filters 8 filters for collimator | ||

| Detection | XFlash® super light element silicon drift detectors, detection down to carbon and up to americium, simultaneous use of two dectectors | ||

| Detection parameters Sensitive area Energy resolution Throughput | 2 x 60 mm2 <145 eV at 600,000 cps input count rate up to 550,000 cps output count rate | ||

| Instrument control | State-of-the-art PC, Windows 10 | ||

| Instrument control functions | Complete control of tube parameters, filters, optical microscopes, sample illumination and sample positioning | ||

| Spectra evaluation | Peak identification, artifact and background correction, peak area calculation, FP quantification, calibrated quantification with standard-based and standardless models using XMethod | ||

| Distribution analysis | "On the fly" measurement, HyperMap capability | ||

| Result presentation | Quantification results, statistical evaluation, element distribution (line scan, mapping) | ||

| Power requirements | 100-240 V (1P), 50/60 Hz | ||

| Dimensions | WxDxH: 815 mm x 680 mm x 580 mm, approx. 130 kg (depending on configuration) | ||

| Quality & safety | DIN EN ISO 9001:2008, CE certified Fully radiation protection system; radiation <1 µSv/h |

-

Unparalleled Stability...

27-03-2019 01:38:04 AM -

The Reference Machine in...

27-03-2019 01:28:20 AM -

SMALL PARTS COUNTER U-60

27-03-2019 01:04:31 AM

- HCMC Office: Block A, Lever 2, Linh Trung Building, No 6-8, Road no 16, Linh Trung Ward, Thu Duc City, HCMC.

- Head Quaters: 427 Le Dai Hanh, Ward 11, District 11, HCM City.

- Hanoi Office: 156A Quan Thanh Str., Ba Dinh Dist., Hanoi City.

- Phone: +84-28-66865303

- Mobile: +84 982 427 168

- Email: dung@ngocminh-ise.com

- Website: http://ngocminh-ise.com